Commercial EPDM Roofing Systems for Flat & Low-Slope Buildings

Why Choose EPDM?

The Rubber Roof Engineered for Decades of Performance

Thermoplastic poly-olefin’s close cousin, EPDM (ethylene-propylene diene monomer) has protected commercial roofs for more than 60 years. Its flexible black-or-white sheets resist UV, ozone, hail, and sub-zero temperatures while keeping installed costs among the lowest in single-ply roofing. Partnering with theRoofers.com adds transparent quoting, OSHA-certified installation teams, and end-to-end project documentation, including optional drone photo logs of seams and details.

Benefits of

EPDM Roofing

Why Building Owners Trust EPDM:

Long Service Life (40–50 years)

Independent studies and manufacturer data indicate EPDM can exceed 30 years and may reach 50+ years with proper design and maintenance.

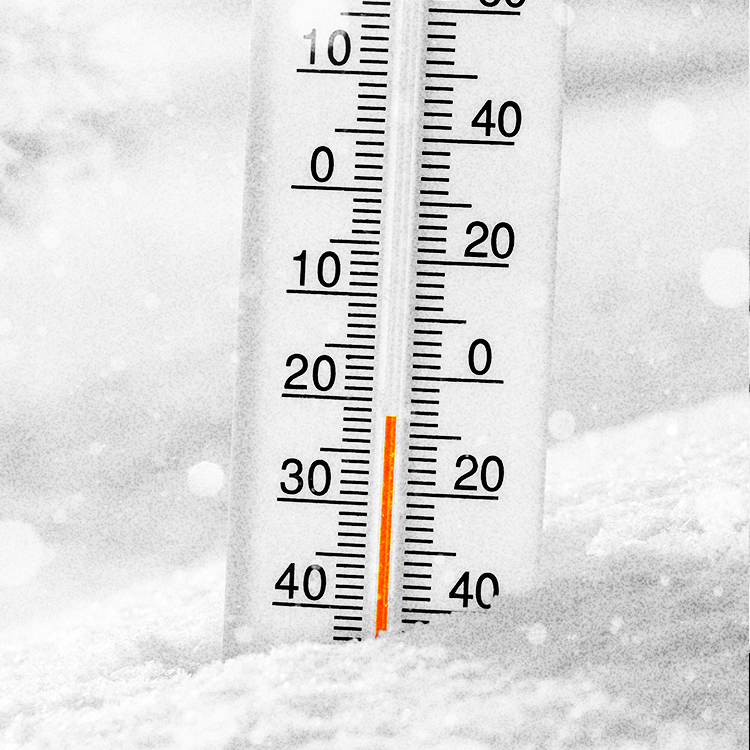

Cold-Climate Flexibility

Membrane remains pliable at very low temperatures (down to approximately −40 °F to −49 °F, product-dependent), handling freeze–thaw cycles that can split rigid systems.

Cost Efficiency

National installed averages typically run $4–$10/ft², with recent project ranges often $7.43–$13.00/ft² depending on scope, access, and labor markets. Many projects price lower than PVC on a per-square-foot basis.

Low-Maintenance, Easy Repair

EPDM’s elasticity and tape-seam technology make small punctures and details straightforward to patch, helping control lifecycle costs.

Sustainability

EPDM can be recycled through established programs and contributes to lower environmental impact across service life compared with many alternatives.

Black Color = Energy Savings

Black EPDM absorbs winter sun in heating-dominated climates, while white EPDM improves solar reflectance for cooling savings.

Installation Services

Expert EPDM Roof Installation & Replacement

theRoofers.com partners exclusively with insured, OSHA-certified commercial contractors who specialize in single-ply systems. Whether you’re retrofitting a 60,000 ft² distribution center or installing a new roof on a retail plaza, our teams recommend the right assembly and thickness for your climate, wind zone, and budget:

Fully Adhered – lightweight and secure, ideal for high-uplift zones and irregular decks.

Mechanically Fastened – fast install with predictable performance and reduced adhesives.

Ballasted – economical on very large roofs; stone ballast adds thermal mass.

Every project is documented with before/after drone imagery and a digital punch-list you can share with insurers and facility managers.

Ideal Applications

Where EPDM Excels:

At theRoofers.com, we partner with OSHA-certified commercial roofing contractors who specialize in professional EPDM installation for:

Repair & Maintenance SERVICES

Keep Your EPDM Roof

Performing for Decades

Even the toughest rubber membrane benefits from routine care. Our certified partners offer annual or semi-annual plans including infrared moisture scans to catch seam lift, punctures, or saturated insulation early. Scheduled upkeep:

Extends service life toward the top end of the range

Protects manufacturer warranties and lowers insurance risk

Prevents disruptive, high-cost emergency calls

Small issues fixed now can prevent six-figure tear-offs later.

Book a preventative service visit today.

Frequently Asked Questions

EPDM Roofing FAQ

Commercial installs average $4–$10 / ft² nationally, with many New England projects running $7.43–$13.00 / ft² due to labor and snow-load fastening requirements. Get a site-specific quote for precise budgeting.

With routine maintenance, EPDM commonly exceeds 30 years and can approach 40–50 years in northern climates.

Yes—especially flat and low-slope structures such as warehouses, schools, and retail centers. For heavy chemical exposure or strict reflectivity targets, PVC or TPO may be recommended.

Schedule semi-annual inspections, clear debris, reseal penetrations, and patch minor punctures immediately.

Properly engineered assemblies meet local snow/wind loads using ASCE-7 and IBC guidance; ballast weight or fastening density is adjusted per design.

White EPDM provides high solar reflectance that may qualify for local utility rebates or state programs.